CENA Hessen is the project coordinator. In addition to ongoing coordination, CENA Hessen is also taking the lead in preparing the overall study. The competence center is also working on the topic of regulation.

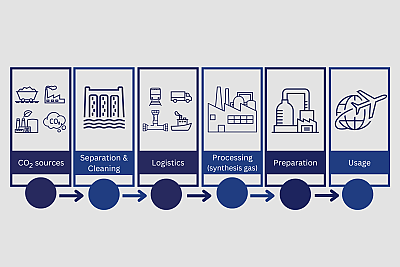

The Carbon4PtL project is developing an integrated concept for the utilisation of CO2 in the production of e-fuels for aviation. By analysing the entire value chain, central process points are optimised and the basis for industrial scaling is created. In this way, we are making a decisive contribution to the defossilisation of the transport sector.

The aim of Carbon4PtL is to develop a feasibility study on how carbon dioxide (CO2) can be made available sustainably and economically for power-to-liquid (PtL) production. Other fields of application - such as the chemical industry, which also needs alternatives to fossil carbon - also benefit from analyses of future sources of CO2. Critical process points, such as the purity of the CO2, will be analysed and the sustainability and economic viability of the processes evaluated. To this end, CENA Hessen is working with research institutes and industrial partners in the Carbon4PtL project from 2024-2026.

CENA Hessen is the project coordinator for Carbon4PtL and is investigating the extent to which the existing regulatory framework would need to be adapted in order to make CO2 usable as a product. We are looking at the regulatory framework for the processing of carbon sources for fuel production, analysing existing barriers to investment and developing recommendations for action based on this.

The project is being funded with around 0.63 million euros by the Hessian Ministry of Economics, Energy, Transport, Housing and Rural Areas (HMWVW).

The planned feasibility study creates transparency about the unavoidable and biogenic CO2 and the prospective emission performance based on various scenarios. This enables targeted CO2 management measures and their monitoring. By using real data from Hessian CO2 point sources, forecasts on their future development and taking into account the specific conditions in Hessen, the results and findings of the study should be as close to reality as possible. Alternative utilisation options for CO2 are partially taken into account in this study, as these also require purifying and logistics. It would be possible to utilise CO2 as a raw material (Carbon Capture and Usage, CCU) outside of PtL fuels, e.g. in the chemical industry, or possibly to transfer it to storage sites (Carbon Capture and Storage, CCS). CCS refers to CO₂ emissions from plants for which no alternatives to combustion or manufacturing processes without CO2 emissions are likely to be available in the future. Wherever reasonably possible, the avoidance of emissions has priority.

Carbon4PtL covers the entire supply chain from possible CO2 point sources to logistics and CO2 utilisation in PtL synthesis. Individual PtL plants already exist, but there is no scientific analysis that covers the entire CO2 supply chain and thus sheds light on issues relating to the scaling of industrial CO2 utilisation.

In addition to green hydrogen, CO2 is also required for the production of e-fuels. There are various possible sources for this: while biogenic sources (e.g. used cooking oil) tend to be limited, extraction from the atmosphere (direct air capture, DAC) is complex and currently still very expensive due to the low CO2 concentration. Industrial point sources are another source of CO2. The majority of CO2 emissions from point sources originate from the combustion of fossil fuels. However, there are also process-related emissions, e.g. in the cement and lime industries. Although these cannot be avoided by switching to Renewable energies, they offer the potential to be utilised for the production of e-fuels in the future.

The consortium is made up of five project partners and is supported by four associated partners from industry.

The partners in the Carbon4PtL project include CENA Hessen, the Centre for Environmental Systems Research (CESR), the Frankfurt University of Applied Science (FRA UAS), INERATEC GmbH and the Provadis School of International Management & Technology AG. Associated partners are Dyckerhoff GmbH, Fritz Winter Eisengießerei GmbH & Co. KG, HIM GmbH and Infraserv Höchst GmbH & Co. Höchst KG.

The Centre for Environmental Systems Research (CESR) at the Kassel Institute for Sustainability at the University of Kassel records the CO2 point sources in Hessen in an emissions register. The future availability of CO2 from point sources is estimated on the basis of a subsequent scenario analysis.

The Provadis School of International Management & Technology AG conducts a technical-economic analysis, since a positive economic assessment of the overall project is a prerequisite for its subsequent realisation, in addition to its technical feasibility. A life cycle analysis quantifies the environmental impact in detail, such as the CO2 footprint and resource consumption.

Dyckerhoff GmbH is a manufacturer of cement and ready-mixed concrete and is part of the Italian company Buzzi.It operates seven cement plants in Germany and has its headquarters in Wiesbaden.

HIM GmbH is one of the leading players in the German recycling industry.The company operates specialised facilities at five locations in Germany where hazardous waste is pre-treated, handled, chemically-physically or thermally treated and, if necessary, safely stored. HIM is based in Biebesheim and is part of the Indaver Group.

Infraserv Höchst GmbH & Co. Höchst KG is the operator of Industriepark Höchst. As an industrial services provider, its responsibilities include energy supply, waste disposal, facility management and security.

Head of CENA Hessen

Centre of Competence for Climate, Environment and Noise Protection in Aviation (CENA Hessen)

Project Manager CO2-Strategy

Centre of Competence for Climate, Environment and Noise Protection in Aviation (CENA Hessen)